Precision mechanical machining involves the creation of intricate components and parts with tight tolerances, demanding a meticulous approach to cleanliness. The cleanliness of metal surfaces is crucial in ensuring the quality and performance of precision machined parts. In this article, we will explore effective techniques for cleaning metal surfaces in precision mechanical machining.

Understanding the Importance of Cleanliness

Understanding the importance of cleanliness in precision mechanical machining is paramount to ensuring the quality and functionality of machined components. Several key aspects highlight the significance of maintaining clean metal surfaces throughout the machining process:

Precision and Accuracy

Cleanliness is directly linked to precision and accuracy in machining. Even microscopic contaminants, such as dust particles or residual oils, can adversely impact the precision of measurements and the overall accuracy of machined parts. Maintaining a clean environment and surfaces is essential for achieving tight tolerances and meeting the exact specifications of designed components.

Tool Longevity

Machining tools, including cutting tools and milling equipment, can experience accelerated wear and tear if exposed to contaminants. The presence of abrasive particles or corrosive substances on metal surfaces can compromise the integrity of tools, leading to reduced tool life and increased maintenance costs. Clean surfaces contribute to the longevity of machining tools, ensuring consistent performance over time.

Surface Finish Quality

The final surface finish of machined components is highly dependent on the cleanliness of the materials and machining environment. Contaminants on metal surfaces can cause imperfections, scratches, or uneven finishes, affecting the aesthetic and functional qualities of the end product. Clean surfaces are essential for achieving the desired surface finish and enhancing the overall quality of machined parts.

Corrosion Resistance

Many metals used in precision machining, such as stainless steel and aluminum, are susceptible to corrosion when exposed to environmental factors or contaminants. Clean surfaces are less prone to corrosion, ensuring the longevity and reliability of machined components, especially in applications where resistance to rust or degradation is crucial.

Quality Assurance

Cleanliness is a fundamental aspect of quality assurance in precision machining. Meeting stringent quality standards and specifications requires meticulous attention to detail throughout the machining process. Clean metal surfaces contribute to a controlled and consistent manufacturing environment, reducing the likelihood of defects and ensuring that the final products meet or exceed customer expectations.

Ways to clean metal surfaces in mechanical processing

Compressed Air or Vacuum Cleaning

Before applying any liquid cleaning agents, use compressed air or a vacuum to remove loose debris, chips, and dust from the metal surfaces. This initial step helps prevent abrasive particles from causing scratches during subsequent cleaning processes.

Solvent Cleaning

Solvent cleaning effectively removes oils, greases, and other organic contaminants. Choose a suitable solvent, such as isopropyl alcohol or acetone, and apply it using a clean, lint-free cloth or brush. Wipe the metal surfaces thoroughly to dissolve and remove residues. Ensure proper ventilation and wear protective equipment when using solvents.

Alkaline Cleaning

Alkaline cleaning is suitable for removing stubborn residues, including cutting fluids and coolants. Prepare a mixture of alkaline cleaner and water, and apply it to the metal surfaces. Use a brush or scrubbing tool to agitate the solution, effectively removing contaminants. This method is particularly effective for cleaning ferrous metals.

Vapor Degreasing

Vapor degreasing involves exposing metal parts to vaporized cleaning solvents in a controlled environment. The solvent condenses on the surfaces, dissolving and carrying away contaminants. Vapor degreasing is effective for the precision cleaning of intricate parts and is commonly used in industries where stringent cleanliness standards are required.

Steam Cleaning

Steam cleaning utilizes high-temperature steam to remove contaminants from metal surfaces. This method is effective for degreasing and removing oils. Steam cleaning is environmentally friendly and does not involve harsh chemicals. It is suitable for applications where water-based cleaning is preferred.

Drying and Inspection

After cleaning, it is crucial to thoroughly dry the metal surfaces to prevent the formation of water spots or residues. Inspect the surfaces visually and, if needed, use magnification tools to ensure no contaminants remain.

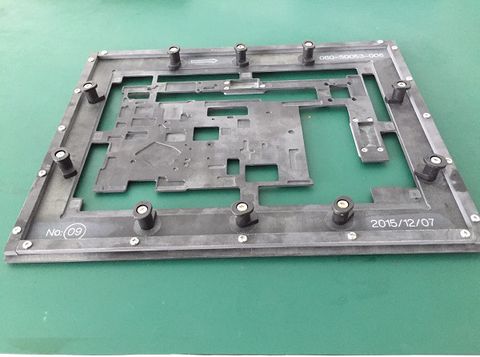

Anttek Vietnam – Prestigious and quality CNC processing

Anttek Vietnam is proud to be a leading CNC designer and machinist, providing high-quality and reliable products to customers. With many years of experience in the field of jig design and processing, Anttek Vietnam has been a reliable partner for domestic and foreign customers.

For details, please contact:

- Address: Lot G07, Kien Hung land use rights auction area, Kien Hung Ward, Ha Dong District, City. Hanoi

- Factory: Lot 6, Lai Xa Industrial Zone, Kim Chung Commune, Hoai Duc District, Hanoi City, Vietnam

- Hotline:( +84)988 688 336

- Email: truong.nx@anttekvietnam.com

- Website: https://anttekvietnam.vn

Achieving clean metal surfaces in precision mechanical machining is a crucial step in ensuring the quality and performance of machined components. By incorporating the right cleaning techniques and following industry best practices, manufacturers can uphold the precision and reliability of their products, meeting the stringent demands of modern engineering applications.